How much do you know about colour steel plate

How much do you know about colour steel plate

1. Core uses of colour steel plate

colour steel plate is a composite material with galvanised steel or cold rolled steel plate as the substrate, coated with multi-layer organic coating after surface pretreatment, and has the following core functions in the construction field

Structural support: as a load-bearing building material for roofs and walls, it can replace the traditional brick and tile structure;

Protective performance: waterproof, fireproof, corrosion-resistant, adaptable to acid rain, ultraviolet rays and other harsh environments;

Environmental regulation: with heat-insulating core materials (such as polyurethane) to achieve thermal and acoustic insulation, and improve building energy efficiency;

Rapid construction: lightweight and easy to install, suitable for modular building material and temporary facilities

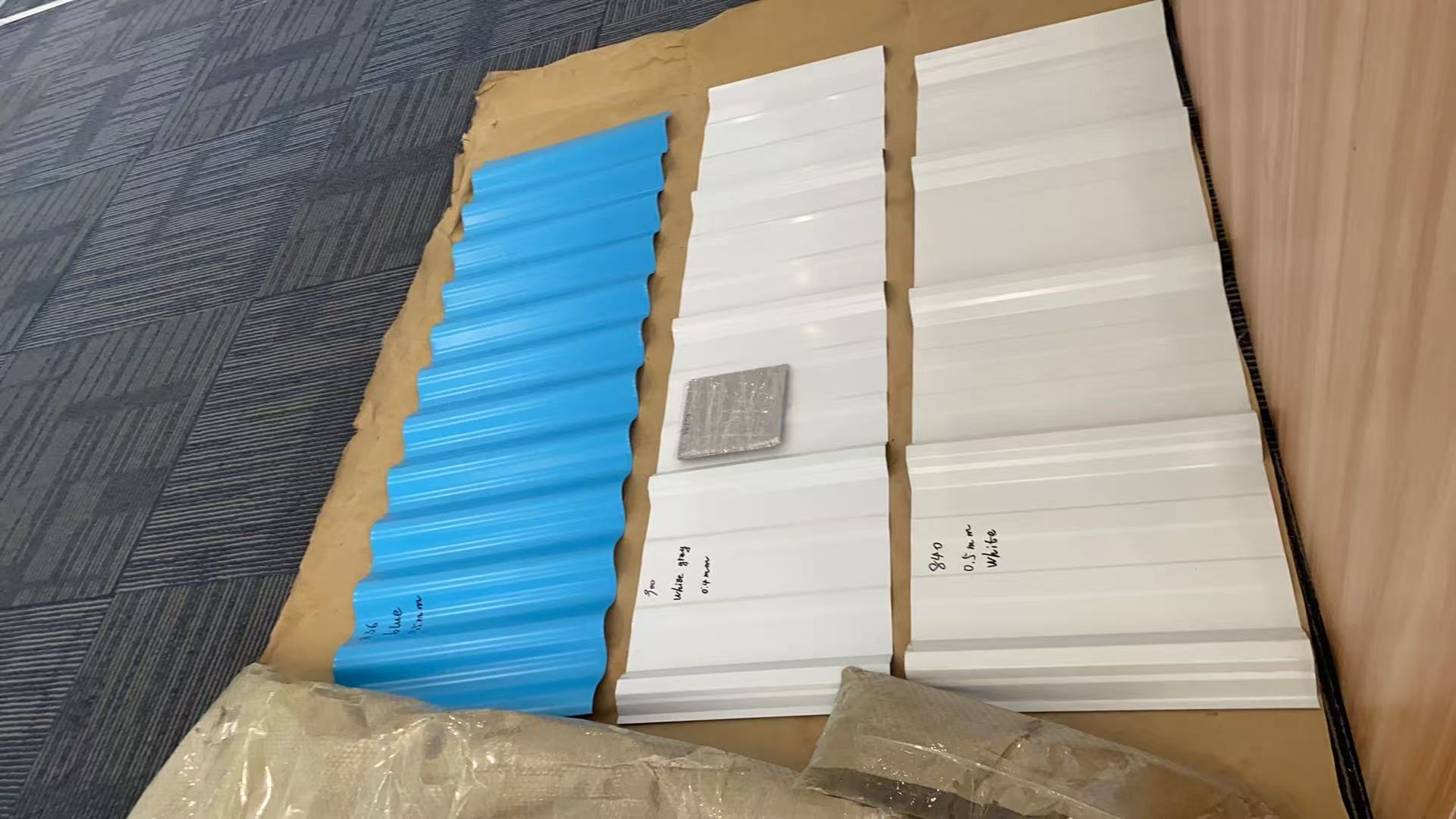

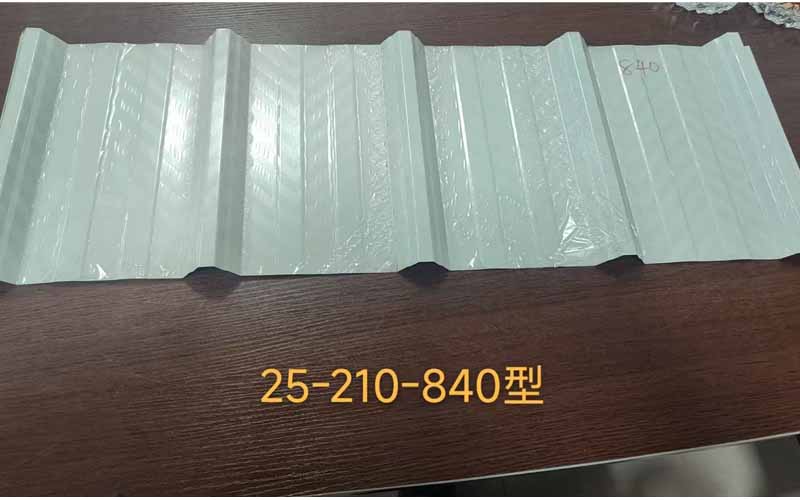

2. Commonly used thicknesses and selection recommendations

Conventional range colour steel plate:

Construction area: 0.5-0.9mm (common thickness);

Special scenarios: such as large span plant or heavy load area, 1.0-1.5mm thick plate can be used.

Suggestions for breakdown scenarios:

Roofing: ≥0.5mm (high demand for wind pressure resistance);

Wall: 0.3-0.5mm (balance between economy and strength);

Cold storage/clean room: need to combine with core thickness (e.g. 50-250mm sandwich panels) to enhance thermal insulation

3. Main application areas

Industrial building materials

Roofing and enclosure structures of factories and warehouses (over 60% building material);

Cold storage, purification workshop (moisture-proof, antibacterial demand scenarios).

Public facilities

Curved roofs of gymnasiums and exhibition halls (high plasticity);

Canopies and station roofs of transport hubs (wind and earthquake resistant).

Civil field

Movable boarding house, agricultural shed (low cost, fast erection);

Residential partitions, decorative facades (rich colour options)

4. coating type and selection guide of colour steel plate

Coating directly affects the durability and applicable environment of colour steel plate

Coating type of building material

Polyester (PE): Cost effective, general weather resistant, suitable for indoor or mild climate zones

Silicone-modified polyester: Improved weather resistance, suitable for coastal or industrial pollution areas

Fluorocarbon (PVDF): Super weathering resistance (over 20 years), self-cleaning, used in landmark building material

Highly weatherable (HDP): UV and chemical resistant for harsh industrial environments.

Selection Recommendations:

Coastal/highly contaminated areas: give priority to fluorocarbon or HDP coating;

Temporary building material : polyester coating can meet the demand;

Clean rooms: choose antimicrobial coatings (e.g. medical grade colour steel sheets)

Star Er is a technology-based construction enterprise committed to promoting scientific and technological innovation to lead future life. We have been specializing in steel construction for more than 10 years.

Our products cover all types of steel structure buildings, including various prefabricated metal building warehouse, steel structure workshops, building material , steel structure poultry houses, steel structure prefabricated houses, etc.