Footing anchors for steel building foundations, how to avoid being pulled out?

Footing anchors for steel building foundations, how to avoid being pulled out?

Steel building Anchor Bolt Damage Forms

What forms of damage may occur to footing anchors pre-buried in concrete foundations under tension?

steel building anchor bolt is pulled bad anchor bolt itself will break or produce obvious plastic deformation. This situation may be a large load and the anchor bolt with a small, or the quality of steel and so on.

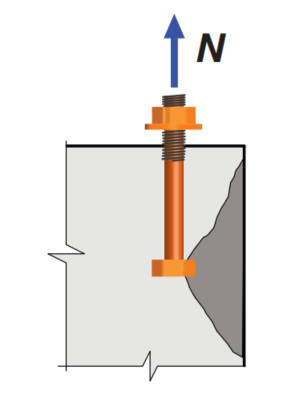

2. Steel building Anchor bolts are pulled out Anchor bolts are pulled right out of the concrete. Anchor bolts are large enough that the transfer of tension depends on the bond with the concrete. When this bond is insufficient (e.g. low concrete strength), the anchor bolt is not securely anchored in the concrete.

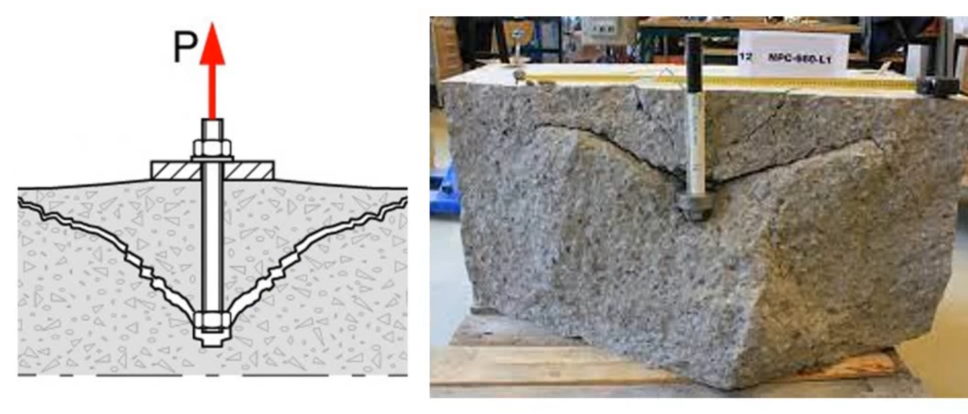

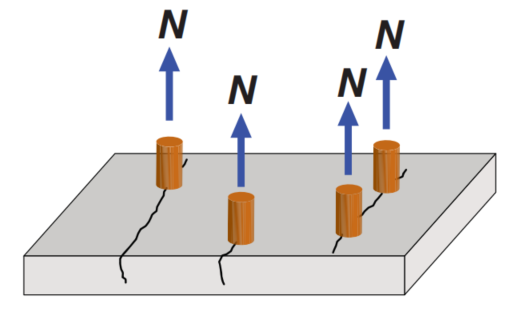

3. Steel building for Concrete rupture Around an anchor bolt, the concrete peels off as a whole or crumbles in large pieces. Anchor bolts are large enough and have a strong enough bond that when the anchor bolt is under tension, this force is transferred to the surrounding concrete. If the concrete is not strong enough or does not have enough reinforcement, the concrete around the anchor bolt will crack and peel off in one piece.

4. Concrete splitting in steel building Concrete will crack in straight lines along the perimeter of the anchor bolts. This is usually due to improper positioning of the anchor bolts (e.g., too close to the edge of the concrete) or existing cracks in the concrete, which result in localized concentrations of stress.

5. Concrete Side Spalling of Steel building When anchor bolts are installed close to the edge of the concrete, the circular rupture pattern of the concrete cannot be fully formed when the anchor bolt with the nut at the bottom is subjected to tensile force, which results in the spalling or bursting of the concrete side first. So make sure there is enough reinforcement at the edge to prevent side bursting, especially if the anchor bolt is a short distance from the edge.

The occurrence of each damage mode is closely related to the strength of the material, the construction process, the relative position of the anchor bolt to the concrete, and the stress distribution.

6.Bolted end plate connection has the comprehensive advantages of less bolts, simple assembly of components, less welding in the factory, all-bolt connection on site,

on-site installation is not affected by the season, easy to dismantle and so on, and now it has become one of the main node forms for the connection and installation of

multi-storey Steel building frame structure and portal frame Steel building components. In assembled steel structure and assembled combination structure, especially in the structure using H-beam and T-beam members, more and more steel members start to use end plate connection node.

Reasonable Steel building design can realize the redundancy and economy of all aspects of the overall coordination, if too much to strengthen a certain aspect, it is easy to ignore the other may appear relatively weak aspects. When a uniform “should not be less than 25d” anchorage length to require, the foundation in order to meet this length, may have to increase the depth of burial or increase the size of the anchor itself and the cost of the foundation will immediately highlight the problem!

This is often the case with design elements for steel-concrete joints, which are more complex and require a more comprehensive design approach to be considered to prevent these multiple damage modes from occurring.

Star Er is a technology-based construction enterprise committed to promoting scientific and technological innovation to lead future life. We have been specializing in steel construction for more than 10 years.

Our products cover all types of Steel building, including various prefabricated metal building warehouse, steel structure workshops, steel structure garages, steel structure poultry houses, steel structure prefabricated houses, etc.