deepen design steel structure

Brand: Xinger

Product origin: China

Delivery time: 15-25 days

Supply capacity: Unlimited

1.Optimize engineering performance and safety

2.Reduce construction costs and waste of resources

3.Improve construction efficiency and quality

Why do you need to deepen design of steel structure.

Deepen design of steel structure can optimize engineering performance and safety

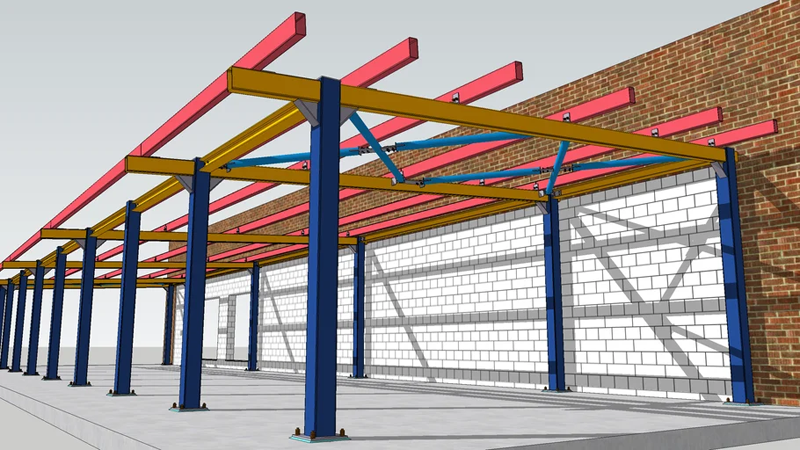

Seismic performance and load carrying capacity can be improved through refined node design (e.g., high-strength bolt connections, welding process optimization) and structural force analysis

Supplementary calculations to the original design to avoid construction risks, such as stress concentrations in complex nodes.

Deepen design of steel structure can reduce the construction cost and resource waste

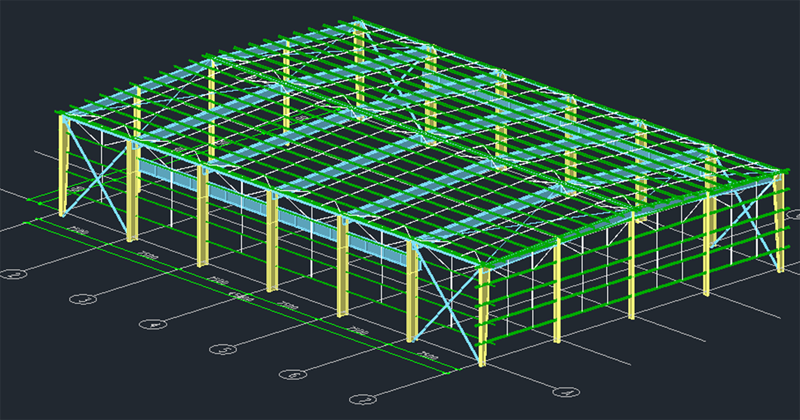

Accurate statistics of material usage through 3D modeling (e.g. Tekla software) to reduce processing residual material.

Optimize component segmentation design to reduce transportation and lifting costs.

Deepen design of steel structure Enhance construction efficiency and quality

Provide standardized processing drawings (including component numbering and weld marking) to shorten the factory production cycle.

Coordinate the collision problems of electromechanical, curtain wall and other specialties through BIM technology to reduce rework.

Core features of deepen design of steel structure

Technical integration

Integration of multidisciplinary knowledge such as structural mechanics, material science, construction technology, etc., which needs to satisfy the design code (e.g., Code for Design of Steel Structures) and construction feasibility at the same time.

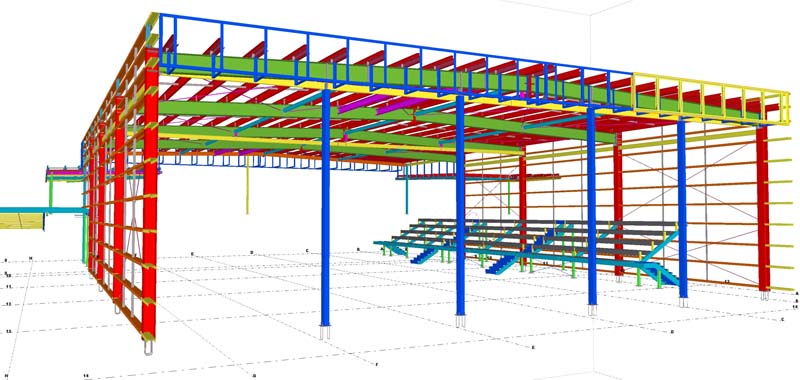

deepen design of steel structure Digitalization and refinement

1:1 3D modeling based on BIM technology (e.g. X-steel/Tekla), automatic generation of machining drawings and bill of materials.

Nodal design accuracy up to millimeter level to ensure the installation matching of complex spatial structures

Dynamic coordination

Real-time communication with civil, MEP and other disciplines is required to reserve penetration holes, equipment mounting positions, etc.

Which scenarios require deepen design of steel structure?

Complex Building Structures

Large-span venues (e.g., stadium grid), shaped and curved buildings (e.g., airport terminals), ultra-high-rise cores

Industry & Infrastructure

Heavy plant buildings (e.g. petrochemical plant frames), steel box girders for bridges, and strong concrete modular structures.

Assembled Buildings

Prefabricated steel houses, modular buildings, standardization of components and rapid assembly through deepening

Which company need to do deepen design of steel structure?

Which company need to do deepen design of steel structure?

Professional Steel Structure Company

General Contractor

Deepening Design Service Organization

Fabricators

Steel structure plants are equipped with a deepening team, directly connected to the conversion of drawings and the optimization of production processes.

Steel structure deepening design is a key link between design and construction, and its value is reflected in the multi-dimensional improvement of quality, cost and efficiency. With the popularization of BIM technology and intelligent manufacturing, deepening design has been upgraded from an auxiliary tool to the core ability of engineering management. High-complexity projects in the fields of architecture, industry and transportation all rely on professional deepening teams, and their necessity will be further highlighted in green building and intelligent construction in the future.