Why do we need to deepen the design

Why do we need to Structure steel deep design?

The core value of Structure steel deep design

Safety and Stability Enhancement

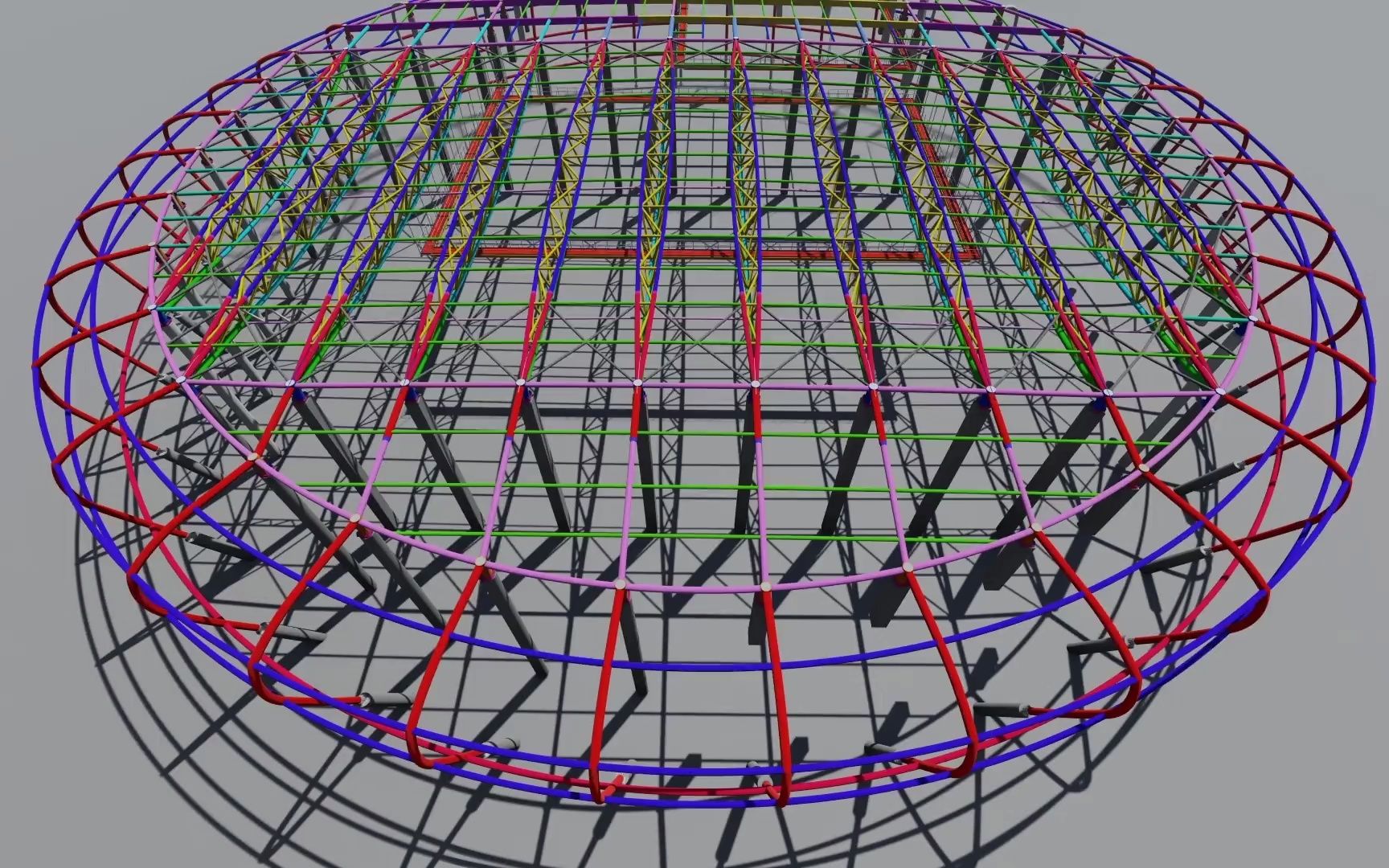

Ensure that the structural stress meets the specification requirements through node strength calculation and component stress ratio analysis.

Optimise details such as the form of weld bevels and bolt spacing to avoid potential safety hazards caused by design defects during construction.

Economic optimisation

Accurate calculation of material usage to reduce steel wastage (case studies show a reduction in steel usage of 5-15%)

Rationalisation of component sections to reduce transport and lifting costs

A leap in construction efficiency

Output standardised machining drawings to achieve assembly line production in factories, shortening the construction period by 20% - 30%.

Prejudging the collision points of civil, M&E and other disciplines to reduce rework on site

Full Life Cycle Management

The BIM model integrates component codes and material parameters to provide data support for later operation and maintenance.

Why it is necessary to Structure steel deep design?

Make up for the blind spot of design

Design institute drawings often lack of construction details (such as lug calculation, temporary support settings), deepen the design to make up for the process nodes.

Matching the actual needs of the project

Adjustment of component dimensions (e.g. splitting of over-restricted components) in relation to factory processing capacity and transport constraints.

Multi-disciplinary collaborative foundation

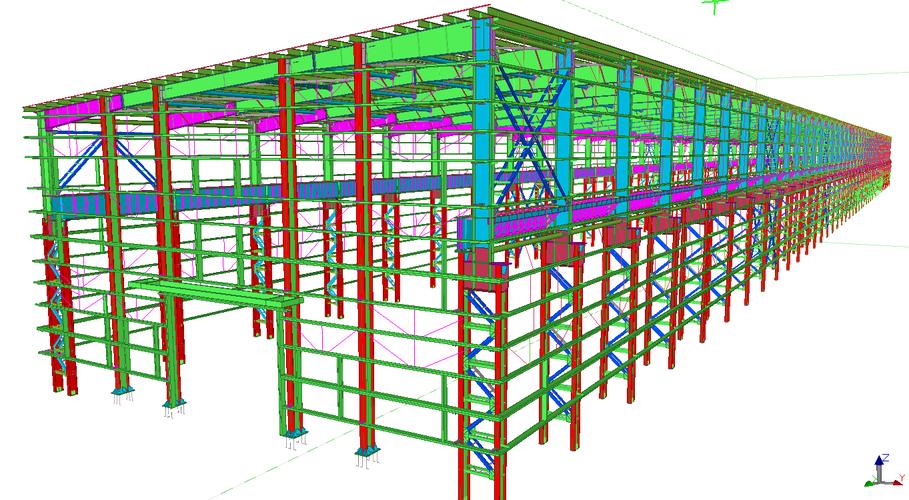

Integration of architectural, curtain wall and M&E models through BIM to resolve spatial conflicts (e.g. precise positioning of pre-embedded holes)

BIM Full Process Service Solution

Planning stage

Scenario feasibility analysis, load simulation Revit+MIDAS Mechanical verification

Further design phase

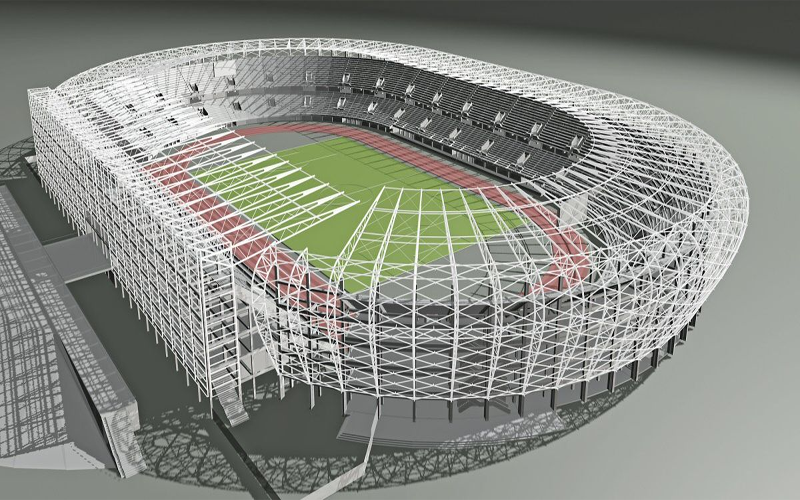

3D modelling, node optimisation, machining drawings Tekla Structures

Construction Stage

4D progress simulation, component tracking, on-site lifting guidance Navisworks+ Intelligent Site System

Cooperation Process

Matchmaking: Provide project information (CAD drawings, technical specifications), we will submit the deepening plan within 48 hours.

Model construction: use Tekla to create BIM model, output collision report and optimisation suggestions simultaneously.

Delivery of results: 12 types of deliverables including processing detail drawings, bill of materials, construction simulation animation, etc.

Star Er is a technology-based construction enterprise committed to promoting scientific and technological innovation to lead future life. We have been specializing in steel construction for more than 10 years.

Our products cover all types of steel structure buildings, including various prefabricated metal building warehouse, steel structure workshops,building material and Structure steel deep design service.

We not only pay attention to the appearance of the product design, but also pay attention to the functionality and intelligence of the product. We advocate the concept of green building, using environmentally friendly materials, energy saving technology, and are committed to creating sustainable homes that meet the needs of future living. We have a passionate and creative team, including talented designers, engineers and technicians. The company continues to increase investment in research and development, actively introduce advanced technology at home and abroad, and is committed to improving the quality and intelligent level of products.