What are the core application advantages of BIM technology in deepening design?

What are the core application advantages of BIM technology in deepening design?

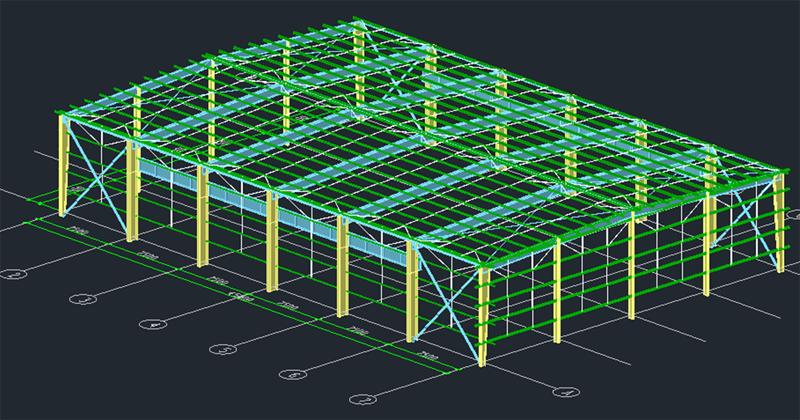

Information Integration and Collaborative Management

Deepening design with All-discipline data integration

BIM technology can integrate multi-discipline models such as architectural, structural, mechanical and electrical, curtain wall, etc. into a unified platform, realizing data sharing and real-time updating and avoiding the problem of information silos in traditional design.

Deepening design can Cross-team Collaboration

supports multi-party teams such as design, construction, and manufacturing to collaborate in the same model to reduce communication errors. For example, the steel structure deepening team and the civil construction team coordinate the details of reinforcement holes and formwork support through the BIM model.

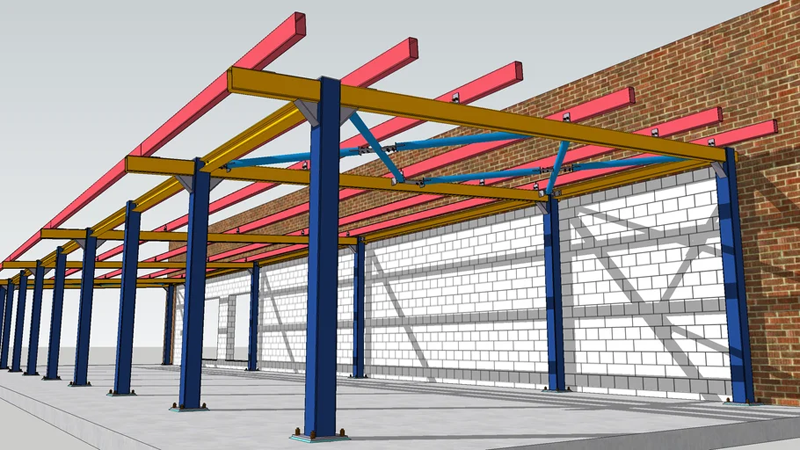

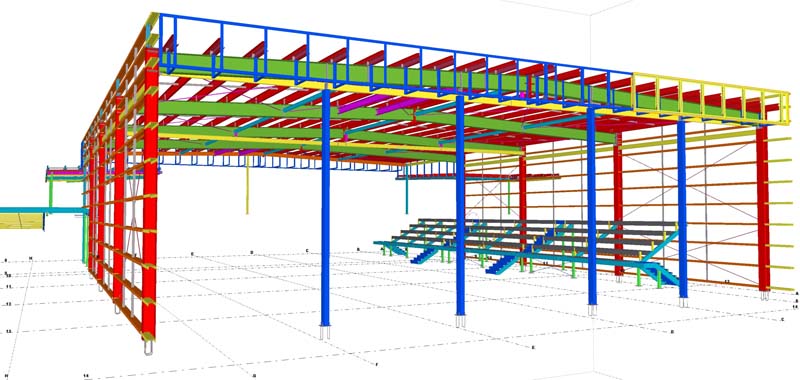

Deepening design throughVisualization and 3D modeling optimization

Accurate design of complex nodes

Through BIM 3D modeling (e.g. Tekla, Revit), it can carry out millimetre-level refinement of the design of shaped surfaces, large-span nodes, and intuitively display the spatial relationship of components, solving the problem of insufficient expression of traditional two-dimensional drawings.

deepening design Dynamic Design Verification

The model is used to simulate real-time scenarios of structural stress and welding process to assist in verifying the reasonableness of nodes. For example, Tekla custom generates complex 3D nodes to optimize weld distribution and stress transfer paths.

Collision detection and clash prediction

Multi-disciplinary collision checking

BIM model can automatically detect spatial clashes between steel structure and M&E pipelines, curtain walls and other disciplines, and adjust the scheme in advance. A project optimized 30% of pipeline crossing problems through collision checking, reducing rework

deepening design Construction Feasibility Verification

deepening design Construction Feasibility Verification

Simulates the construction and installation process to discover problems such as insufficient lifting space and over-limit of component transportation dimensions. For example, the Ganzhou Port Wuyun Terminal project used BIM to prejudge the installation error of the steel mesh frame and accurately adjust the processing size of the components.

deepening design Parametric Design and Efficiency Improvement

Automated Drawing Generation

Processing drawings, bills of materials, and quantity tables can be generated with one click based on the parametric model, increasing efficiency by more than 50% compared with traditional methods. For example, Revit model directly exports component drawings with numbers, reducing manual labeling errors.

Dynamic update and version control

When the design changes, the model parameter adjustment can be linked to update all the related drawings and data to ensure the consistency of information.

Construction Simulation and Cost Control

4D Progress Management

Associate the BIM model with the construction plan to visually simulate the construction sequence of each phase and optimize resource allocation. For example, the simulation of a project found that the time conflict between steel structure lifting and concrete pouring shortened the construction period by 15% after adjustment.

Accurate costing

model automatically counts data such as steel consumption and number of bolts with an error rate of less than 2% to avoid material waste. A plant project saves about 8% of steel consumption through BIM deepening.

The core advantages of BIM technology in deepening design are reflected in: information synergy (breaking professional barriers), design accuracy (millimeter-level error control), cost controllability (optimization of materials and duration), and whole-process data coherence (integration of design-construction-operation and maintenance). With the development of intelligent construction technology, BIM is being upgraded from an auxiliary tool to a core decision support system for project management.

The core advantages of BIM technology in deepening design are reflected in: information synergy (breaking professional barriers), design accuracy (millimeter-level error control), cost controllability (optimization of materials and duration), and whole-process data coherence (integration of design-construction-operation and maintenance). With the development of intelligent construction technology, BIM is being upgraded from an auxiliary tool to a core decision support system for project management.