Q355B galvanized square steel temple renovation project successfully completed

Steel Structure Project Overview

The temple renovation project commissioned by the Australian Heritage Foundation has a total area of 580 square meters and the main steel structure is made of Q355B galvanized square tubes. The project combines modern steel structure technology with traditional religious architectural aesthetics.

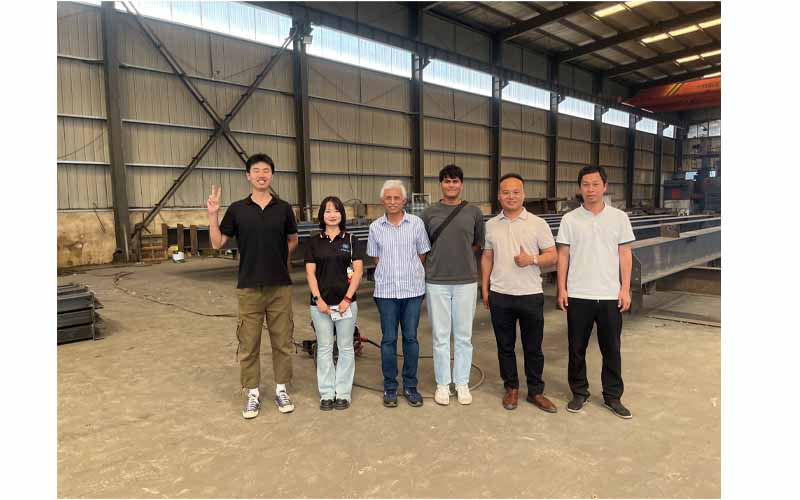

The customer inspection team will come to the factory to inspect the project on June 20, 2025.

Technical highlights and key customer recognition points

Precise adaptation of material performance

The main material is Q355B grade galvanized square tube, with a yield strength of more than 355MPa, a zinc layer thickness of ≥85μm (in line with Australian standard AS/NZS 4680), and passed the 2400-hour salt spray test to ensure corrosion resistance in marine climates.

The customer's on-site sampling mechanical performance report shows: tensile strength 510MPa, elongation 22%, cold bending performance without cracks, fully matching Australia's strict building regulations (NCC 2019)

Difficulties in the renovation project of steel structure

Historical steel structure protection: The technical team used BIM 3D scanning reverse modeling to simulate the load of the original brick and wood structure and customized a "non-contact steel frame support system" to achieve zero-damage reinforcement

Special-shaped node innovation: Developed 3D printing mold casting technology for temple eaves and brackets, completed 287 non-standard nodes, with an accuracy error of ≤0.5mm (customer actual measurement data)

Project summary: The international leap from manufacturing to “intelligent manufacturing”

Material upgrade of steel structure: Q355B galvanized square tube weather resistance certified by developed countries

Technology integration: deep collaboration between digital construction and cultural heritage protection

Service value-added: The full-cycle technical response team received a special letter of commendation from the customer.

Star Er is a technology-based construction enterprise committed to promoting scientific and technological innovation to lead future life. We have been specializing in steel frames for more than 10 years.

Our products cover all types of steel structure buildings, including various prefabricated metal building warehouse, steel structure workshops, steel structure garages, steel structure poultry houses, steel structure prefabricated houses, etc.

We not only pay attention to the appearance of the product design, but also pay attention to the functionality and intelligence of the product. We advocate the concept of green building, using environmentally friendly materials, energy saving technology, and are committed to creating sustainable homes that meet the needs of future living. We have a passionate and creative team, including talented designers, engineers and technicians. The company continues to increase investment in research and development, actively introduce advanced technology at home and abroad, and is committed to improving the quality and intelligent level of products.