The Secret Weapon of Steel Structures: Design Essentials for Connections and Nodes

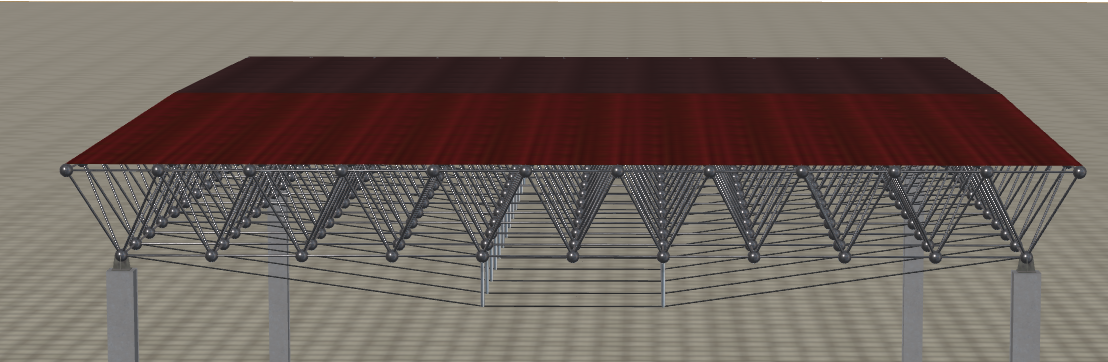

In the field of construction, Steel Structures has become the first choice for modern landmark buildings due to its advantages of high strength, light weight and efficient construction. However, behind these advantages lies an often-neglected but crucial ‘secret weapon’ - the precise design of connections and nodes.

Nodal design: the lifeblood of Steel Structures

Mechanical properties at the core

nodes are required to carry load transfer, resist deformation and distribute stress. The design must ensure that:

Rigidity and strength to meet the multiple tests of self-weight, wind loads and seismic forces

Seismic performance is prioritised, and structural toughness is enhanced by controlling plastic deformation and energy dissipation capacity.

Structural simplicity and construction feasibility

The design of the nodes needs to be balanced between factory prefabrication and on-site installation efficiency:

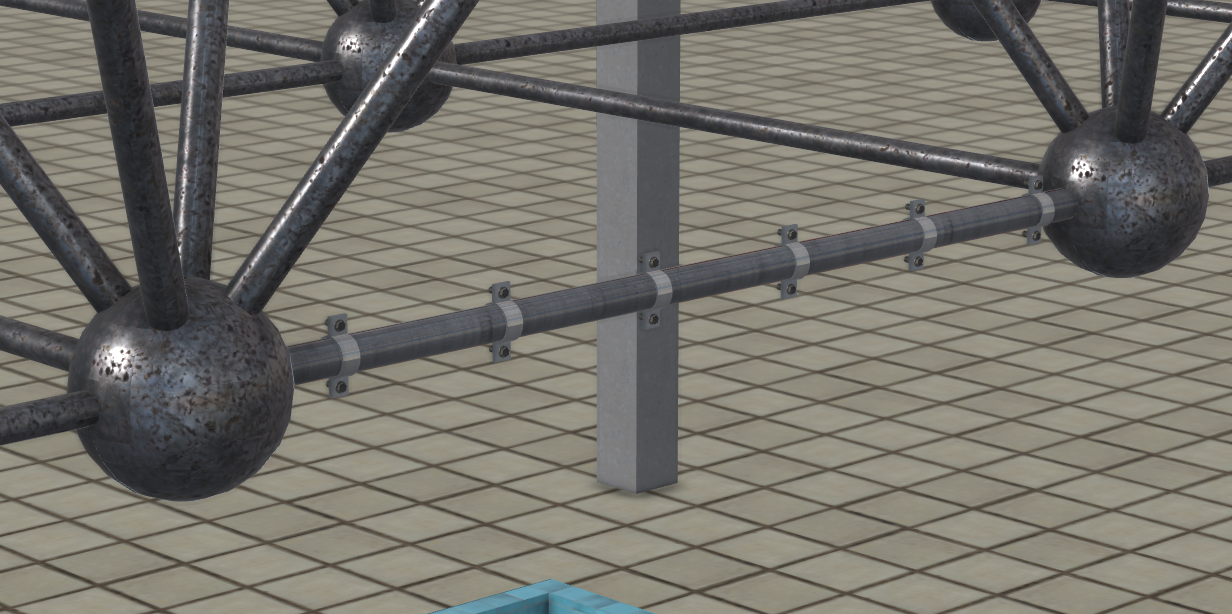

Avoid stress concentrations caused by overlapping weld seams, and give preference to standardised bolted connections.

Leave more than 20mm gap between the components to prevent welding deformation.

Thickness of node plate ≥ 6mm, the size of the manufacturing error to be accommodated

Three connection technologies: empowering the diversity of steel structures

Welded connection - high efficiency but requires precise control

Advantage: material saving, good structural continuity, suitable for rigid nodes of beams and columns;

Challenge: need to match the material of the welding electrode (e.g. Q235 steel with E43-type electrodes), and strictly control the temperature to prevent deformation

High-strength bolted connections - the key to seismic resistance

Friction-type bolts rely on preload to resist shear and are suitable for frames in seismic zones;

Compression-type bolts have a high load-bearing capacity but need to be calculated for the compressive strength of the borehole wall

Design of critical parts: details that determine the stability of steel structures

Rigid nodes of beams and columns

transverse stiffening ribs must be added at the positions of the column webs corresponding to the flanges of the beams;

node domain width/thickness ratio λn,s ≤ 0.8 (for conventional buildings) or 1.2 (for light buildings), with plug-welded reinforcing plates in case of exceeding the limit.

Column footing nodes

Articulated column footings reduce bending moments and are suitable for scenarios with low lateral forces;

Shear keys are required for end-bearing column footings to prevent base plate slippage.

Technological innovation: digital reconstruction of Steel Structures node design.

Star Er is a technology-based construction enterprise committed to promoting scientific and technological innovation to lead future life. We have been specializing in Steel Structures for more than 10 years.

Our products cover all types of steel structure buildings, including various prefabricated metal building warehouse, steel structure workshops, steel structure garages, steel structure poultry houses, steel structure prefabricated houses, etc.