How to optimise the wind-resistant design of Southeast Asian plants

In view of the frequent occurrence of typhoons in Southeast Asia, the optimisation of the wind-resistant design of the Steel plant requires a comprehensive approach from the structural selection, material technology, construction technology and other dimensions, the following are the key optimisation strategies.

Optimisation of Steel plant structural design

Strengthening of wind-resistant column system

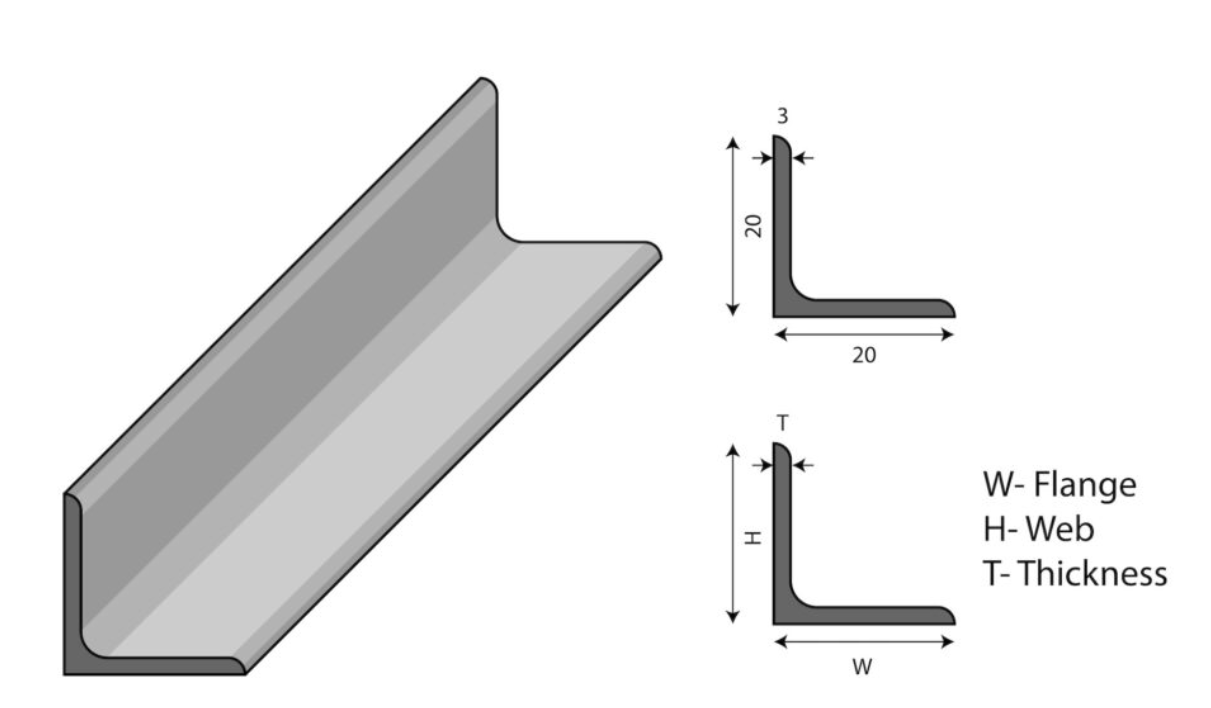

Adopting double-limb wind-resistant column system, H-type steel columns with spacing ≤6m are set up on both sides of the plant's mountain wall (cross-section 400×200×16×20mm is recommended), which together with the cross-bracing form a spatial truss structure, with the side-shift-resistant stiffness increased by more than 30%.

Optimise roof connection nodes, increase 25% of high-strength bolts (e.g. M24 10.9 grade bolts), weld triangular stiffening ribs at the nodes to ensure that the wind load transfer path is continuous.

Roof and enclosure system wind exposure resistance design

Steel plant Adopt sloped roof with slope ≥15° to reduce the wind pressure concentration effect, together with 360° upright edge-locked metal roof panel system, the wind exposure resistance is up to 3.5kPa.

Encrypt wall purlins to a spacing of 1.2m, adopt Z-type cold-formed thin-walled Steel plant and set up spring-clamped fasteners with the wind-resistant columns, and allow a deformation margin of ±30mm.

Material and anti-corrosion technology upgrades of Steel plant

Application of High Weather Resistant Steel plant

S550MC high strength steel (yield strength ≥550MPa) is used for the main structure, which reduces weight by 15% compared to Q345B and improves wind resistance.

Aluminium-zinc plated steel sheet (AZ150) is used to extend the corrosion-resistant life by 2-3 times compared with ordinary galvanised sheet, which is especially suitable for the high salt spray environment in coastal Southeast Asia.

Steel plant Dynamic Wind Load Adaptation Technology

Installed wind pressure sensors for real-time monitoring, together with the adjustable damper system, automatically activate the energy-consuming device when the wind speed is ≥25m/s.

Installation of deflector plates at the edge of the roof, optimising the deflector angle through CFD simulation (20-30° recommended) to reduce the risk of vortex vibration.

Construction Technology Innovation for Steel plant

Modular prefabricated construction

Wind-resistant columns and roof beams are pre-assembled into 6m x 6m standard modules in the factory, and on-site lifting errors are controlled to be ≤3mm.

Wind tunnel simulation with BIM technology is used to identify stress concentration areas in advance, and the optimisation rate can be up to 40%.

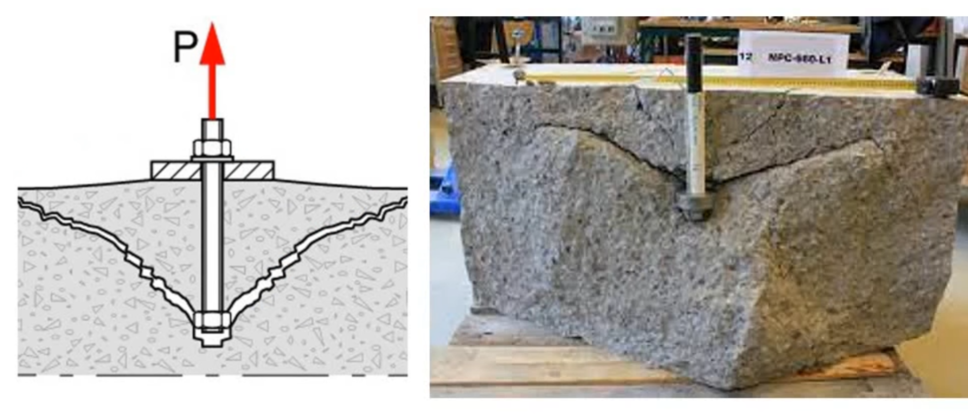

Special programme for foundation treatment of Steel plant

Adopt pile-raft composite foundation in the soft ground area, pile diameter ≥ 400mm, depth of penetration into the soft layer into the holding layer ≥ 3m.

Set up concrete anti-slip piers, the spacing corresponds to the wind-resistant columns, and form a double anti-elevation system through the pre-embedded ground bolt.

Star Er is a technology-based construction enterprise committed to promoting scientific and technological innovation to lead future life. We have been specializing in steel construction for more than 10 years.

Our products cover all types of steel structure buildings, including various prefabricated metal building warehouse, steel structure workshops, steel structure garages, steel structure poultry houses, Steel plant , etc.